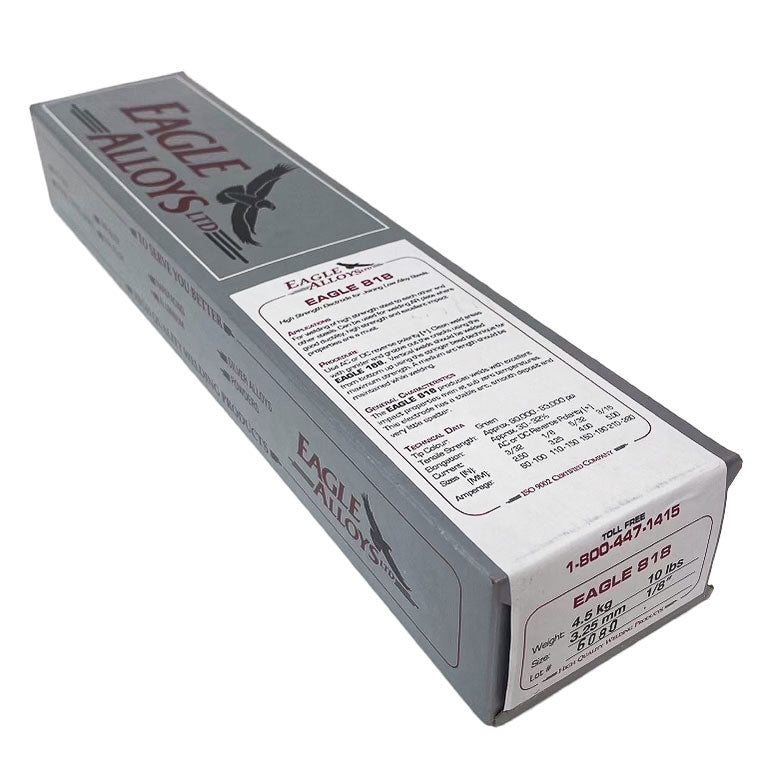

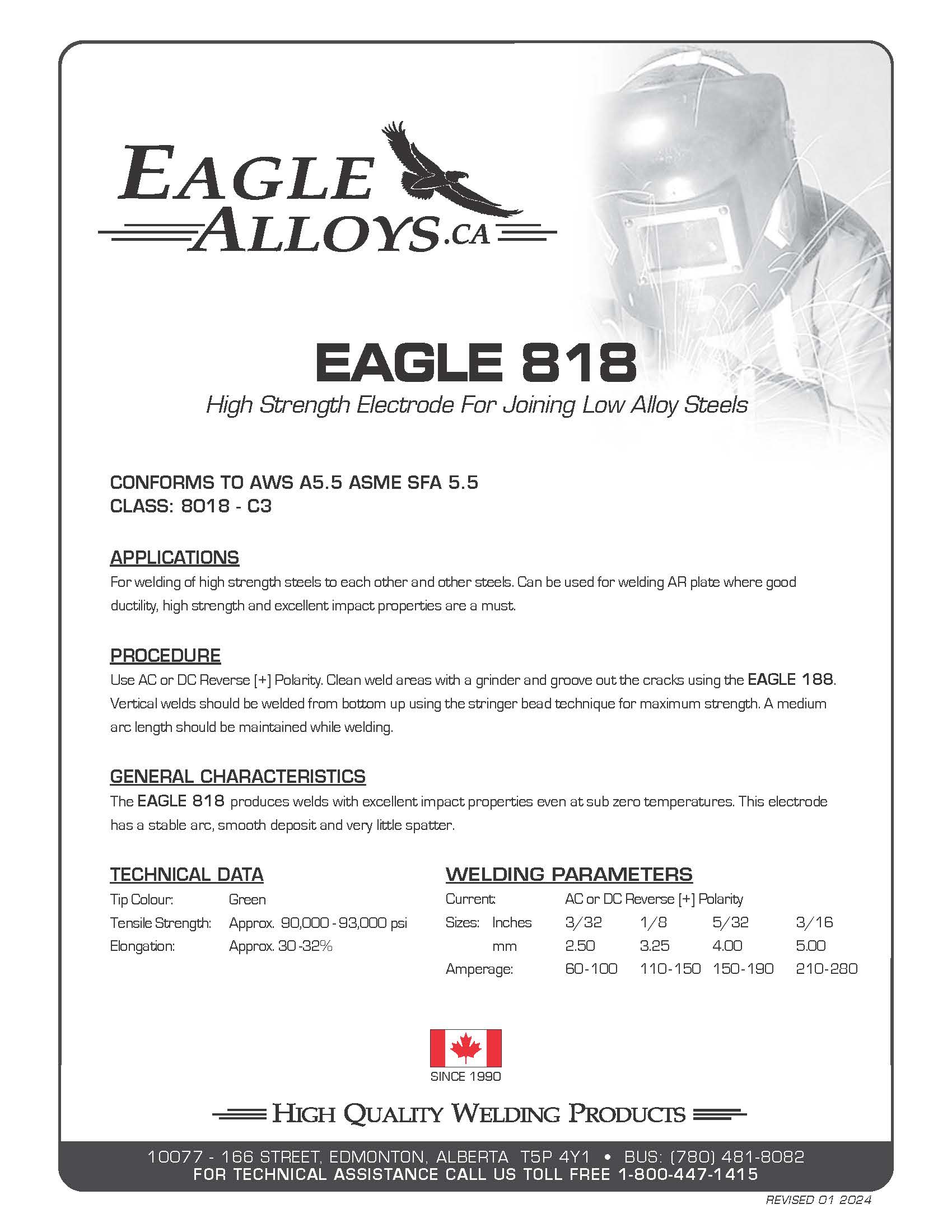

Eagle 818

$116.50 CAD

Free Shipping within Canada

High Strength Electrode For Joining Low Alloy Steels

CONFORMS TO AWS A5.5 ASME SFA 5.5

CLASS: 8018 - C3

Eagle 818 Safety Data Sheet SDS

Eagle 818 SDS Data Sheet (French)